Why the Maker Movement Matters: Part 1, the Tools Revolution

Just like the internet before it, the Maker Movement is revolutionizing manufacturing, with implications for startups and jobs.

In the years when I was visiting and learning about factories in China, my dominant emotion was, I can’t wait to tell people about this! Of course everyone “knew,” in general terms, about the rise of Chinese manufacturing and the country’s role as workshop-to-the-world. But the experience of seeing the factories that turned out computers and smart phones and everything else was so different from hearing about “low-wage Chinese sweatshops” that I thought, people really have no idea.

Sure, low wages and lax-to-nonexistent regulatory and environmental standards were big advantages. But it was mainly the speed of the industrial ecosystem in places like Shenzhen that was so amazing. And the density of all elements of the supply chain — if you needed a certain kind of keyboard or connector, there were five suppliers to choose from within an hour’s drive.

And one more underappreciated element was essential: the new tools of connectivity and logistics that allowed a customer in Chicago to shop online for a smartphone, and have the customized specs conveyed instantly to a production line in China, where the order would be put together and then taken to the airport in Hong Kong for airfreight back to the U.S. These new tools really mattered: China had had low wages for a very long time (and they were beginning to rise fast in these factory zones); it had abused the environment for years (and was trying to clean up). But it was only the knitting-together of information and logistics that allowed Chinese factories to be so directly incorporated into the world production-and-marketing system. That’s the story I told nine years ago in “China Makes, The World Takes,” centered on a company that had pioneered this kind of connection.

I have had a similar feeling in recent years as I’ve seen outposts of the “Maker Movement” across the United States: This matters! People should pay attention! In this and the next few dispatches I’ll explain why I think so, and give illustrations from Kentucky, Oregon, South Carolina, California, and elsewhere.

I imagine that many readers might have heard of this movement or seen one of its Maker Faires. But my guess is that most people who aren’t directly involved think of it as fringe and hobby-minded, artsy-and-craftsy and hip rather than a serious economic, technological, and city-development force. I’ve come to disagree, and let me lay out some of the reasons why.

The Background

First, the lay of the landscape: You can see information about the national Maker Faire cycle here, for information about shows and displays. The next big event on the calendar is the National Maker Faire, in DC two weeks from now. You can read here about MakerCon, which I’ve been to and enjoyed, and go here for Make: magazine, to which I subscribe. In two weeks the White House will have events for the National Week of Making, with more information here. Make: had a story on the Maker City Initiative here; Peter Hirschberg has a speech explaining the concept here; and the Institute for the Future had an early report here.

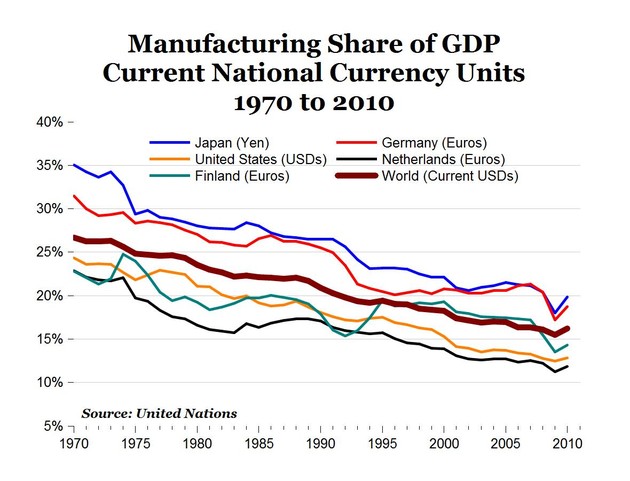

Now, what this movement is and why it matters. Everyone who has heard a recent political speech, listened to a talk show, or looked at the “Made in China” labels in retail stores is familiar with the idea that “America doesn’t make things any more.” There are obvious reasons, and some less obvious ones, why people feel this way. A certain kind of high-volume production certainly has shifted from the rest of the world to China (and elsewhere) in the past generation. As economies get richer, the relative share of manufacturing in their output and their workforce inevitably goes down (as it does for farming—even as absolute output in both categories keeps going up), because service sectors are growing faster. This is true even of economies which much more aggressive pro-manufacturing industrial government policies and corporate practices, like Germany and Japan:

And as manufacturing efficiency grows up, the share of manufacturing jobs goes down even faster than the output share. Everyone’s grandfather worked in a factory; each generation, fewer do.

So there is a real change—fewer Americans have jobs in manufacturing—that seems even larger than it is, because of the kinds of things America still makes. Consumers naturally mainly see consumer goods: TVs, electronics, gadgets, clothes. Those are the fields in which production has disproportionately shifted overseas. Walk into a WalMart or Costco, and just about everything seems to come from China. The higher-end capital goods or scientific equipment from U.S. manufacturers rarely comes before our eyes. (The main exception is Boeing airplanes, with GE or Pratt & Whitney engines.) We see the “assembled in China” labels on Apple computers and phones and over-interpret what that means. The labels conceal the reality that the most valuable parts of a Mac or iPhone come not from China but from richer countries like Japan, Germany, South Korea, and very significantly from the United States.

To wrap this up for now: yes, manufacturing is in relative decline across the developed world, although most Americans think the situation is worse than it really is. And yes, the decline of high-wage, mass-employment manufacturing is part of the worsening pressure on median-income earners, also around the world. So anything that can spur new manufacturing is a plus—with an emphasis on the new, given the repeated findings by the Kauffman Foundation that essentially all net job creation in the United States is from companies in their first few years of existence. (Explanation here. Short version: Older companies, in aggregate, gradually reduce their total workforce over time, as some go out of business and some get streamlined. Thus, the net job growth is from newly-formed companies.)

What might the maker movement have to do with that? It has made it surprisingly easier for new companies, in manufacturing, to start. Why? It has to do with tools.

New Tools, New Firms

Here’s how I finally understood the difference that a new generation of production tools has made: by comparing it to my own business, writing and publishing.

Everyone in journalism knows the line attributed to A.J. Liebling, in The New Yorker: “Freedom of the press is guaranteed only to those who own one.” Liebling wrote that in 1960. As more-or-less recently as that in historical terms, if you wanted to disseminate your thoughts to people outside your household, you simply could not do it yourself. You had no option but to work through a limited number of powerful, capital-intensive enterprises. You had to convince a newspaper or magazine to publish your writings—because only they controlled the printing presses, delivery networks, and newsstands. (I remember the olden days of wanting to react to something in the news, and then making phone calls or sending letters—!!!, yes, real letters in the mail on paper !!!—to the handful of gatekeepers who ran op-ed pages, hoping you could get their interest.) You had to attract the attention of TV or radio reporters, since only they could get you on the air. If you had a longer story to tell, you had to convince a publishing house to put out your book. Short of going door-to-door with flyers, there was no way to avoid the middleman in this industry. And the people who served as middlemen—the publishers, the broadcasters—were buttressed by the very expensive printing and transmitting equipment they controlled.

Wave after wave of disruption in publishing have been bad for everyone who used to hold that middleman role. (The Atlantic is doing very well right now—so thanks for reading and subscribing!) But the new tools fostered an unprecedented outpouring of expression. Blogs, Tweets, YouTube videos, Instagrammed photos, podcasts, Reddit and Facebook communities, billions upon billions of daily texts messages … One by one many of these might be trivial and some of them destructive. But taken together they produced a totally different form of communication and knowledge, and countless millions of new business operations, all because an advance in production tools.

There’s a similar tools-driven change whose effects are so profound that we never even think about them any more. In the early days of computer use and word-processing, if you wanted to write something electronically, you had to wrestle with a lot of the details of electronic life. The first computer I ever used, in the late 1970s, was one I bought from a peanut-processing warehouse in Ohio; I had to reprogram it to be able to use a writing program called The Electric Pencil. Now people may grumble about Word, Pages, and other programs, but using them requires about as much forethought as picking up a real pencil. In the early days of web design, to put anything online you had to know a lot about layout code. Including pictures, charts, videos, or sounds was so hard you generally didn’t bother. Now you copy an embed code, you click Share or Send or Upload, and the job is done. Tools that were unknown a generation ago are now ubiquitous and have changed everything about communication and expression.

Tools for Making

Something similar is fostering the maker movement. Since the dawn of the capitalist heavy-industrial era, to succeed in manufacturing you needed capital. You needed money for giant production equipment. Blast furnaces if you were making steel, assembly lines if you were making cars, machine tools if you were making engines, coordinated supply chains if you were assembling complex devices. Then you needed distribution arrangements with stores, and lots of inventory for them to keep in the warehouse, and other impediments that collectively made it hard, expensive, high-stakes, and high-risk for newcomers to enter a business.

This is the equation that the tools revolution of the past few years is also changing for manufacturing. A combination of 3D printing (which allows people to make and revise prototypes onsite, and produce certain high-value, low-volume items themselves, rather than going to a factory); much less expensive laser cutters, milling machines, and other sophisticated machine tools; the evolution of Arduino controls, which allow designers to add sophisticated electronic functions without doing all the coding themselves. You could think of this last function as being similar to simple Embed functions for images or videos online.

In parallel with these technological advances have been organizational changes. For instance, the rise of maker-spaces and shared-work site where people can use advanced machinery for free or at very low cost; and the rise of collaborations among universities, community colleges, established companies, and local financiers in fostering hardware entrepreneurs. One of the most ambitions of those collaborative spaces is “Highway 1” in San Francisco. I wrote about its origins in the magazine back in 2012; you can read a report about its latest “Demo Day,” at which maker groups show off their products, in a TechCrunch story here and see a video here. This video from Highway 1 is obviously promotional, but it demonstrates the changes I am talking about and rings true to what I have seen and heard from entrepreneurs there (I have met and interviewed some of the people you see here).

What It Means in Practice

“This would not have been possible ten years ago,” Venkat Venkatakrishnan, the CEO of a unique and famous maker space called FirstBuild, told me in Louisville earlier this year. FirstBuild is unique because it was created by GE, as a subsidiary of its appliance division and as a deliberate effort to bring the nimble maker spirit to its design process.

“What has changed is that the maker movement has figured out a group of technologies and tools which enable us to manufacture in low volume,” Venkat (as he is known) said. Big manufacturers like GE built their business on high-volume, factory-scale, very high-stakes production, where each new product means a bet of tens of millions of dollars. FirstBuild is mean to explore smaller, faster, more customizable options.

“Now you can get a circuit board mill for $8,000. If you are looking for a circuit board for an appliance, earlier the only chance of getting it was from China. Today I can make boards here and ship them out quickly. Similarly with laser cutters—not big ones but small ones, where I can cut metal right here. It’s a huge advantage, and these things did not exist ten years ago. In those days you couldn’t hack the kind of creative solutions we are seeing now.”

Tomorrow FirstBuild and its parent GE Appliances division are expected to complete a long-announced deal that will transfer ownership to the giant Chinese appliance maker Haier. (GE had previously planned to sell to the Swedish firm Electrolux, which has a much bigger presence in the U.S. market than Haier does, but it called off the deal last year after resistance from U.S. anti-trust regulators.) Both GE and Haier have said that that all factories and facilities will stay where they are (Electrolux had planned a move to its existing sites in North Carolina); that the GE Appliance and FirstBuild management will be unchanged; and that the FirstBuild start-up mission will continue too.

That’s the high-level corporate news. In the next installment, more details on exactly what FirstBuild has underway, how that parallels efforts in other parts of the country, and what this Maker energy might mean for the country’s ability to foster new companies and create better jobs.